Quality control

Quality control

Assuring high quality and safety

through strict inspections by our in-ho laboratory

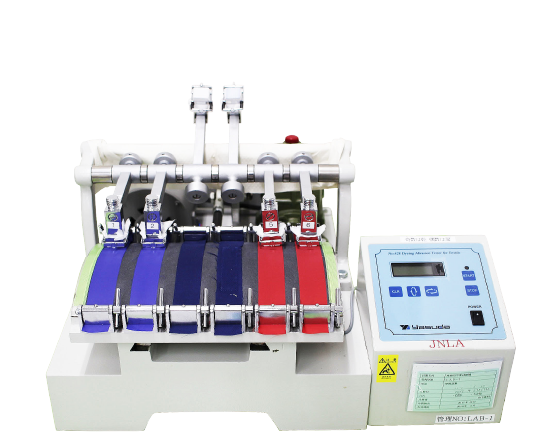

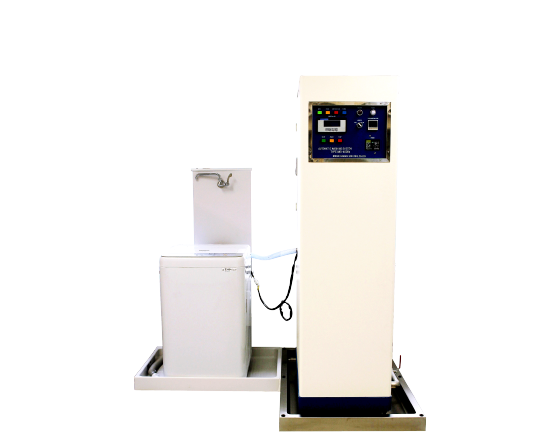

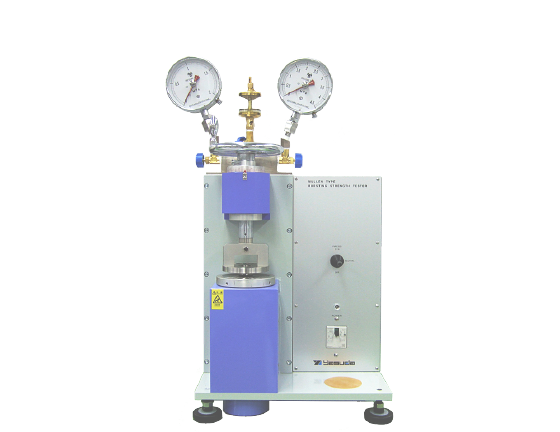

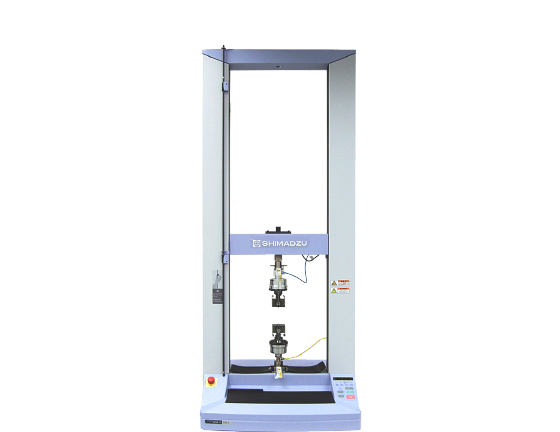

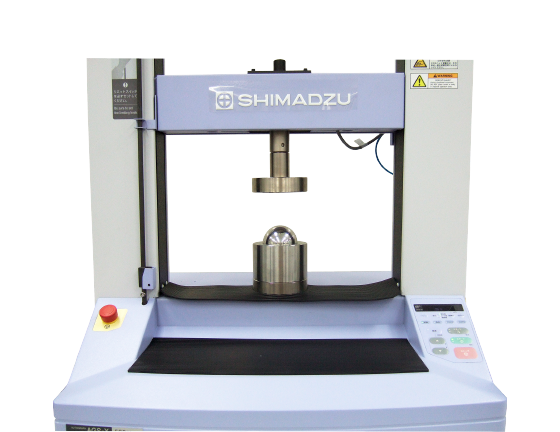

To assure high quality and safety, we have set up an in-house laboratory where we carry out strict inspections complying with JIS and ISO standards for conditions such as durability and color fading. By internalizing inspections rather than entrusting them to an outside agency, we can achieve speedy quality checks for newly developed products from Japanese and foreign manufacturers. This enables quick supply. We believe this to be the value we provide through acting as an intermediary trading company.

Passion for quality

Passion for quality

JNLA

Shimada Shoji has been certified as a testing location that conforms to the requirements of ISO/IEC 17025, a standard set by the International Organization for Standardization and the International Electrotechnical Commision, and was registered as a testing operator under the JNLA system in May 2018. JNLA is the abbreviation for Japan National Laboratory Accreditation System. It is a program under which the national government examines whether testing operators have the technical capabilities needed to conduct JIS testing appropriately and registers those that do. Registered testing operators can issue testing certificates with the JNLA logo as proof of their registration. We strive to supply products with performances that have been proved to be highly reliable by testing under the JNLA system.

Quality control

Quality control Passion for quality

Passion for quality The laboratory that supports quality

The laboratory that supports quality