FEATURE PRODUCT

Innovative absorbent that changes

common knowledge of container transportation

Temperature and humidity are

great enemies of container transportation.

From Japan to China, ASEAN and south Asia. It’s important to solve problems caused by environmental differences in production field where situation changes rapidly.

Especially under harsh circumstances of high temperature and humidity in containers, complaints about rust or mold are inevitable. That’s why keeping product quality plays a significant role in capturing markets.

We can solve

such transportation issues!

Not only during marine transportation, but also during inland transportation, containers go through harsh conditions depending on local climate. Sometimes, humidity may become more than 90%.

EX-DRY (absorbent) will be a strong ally to clear such negative conditions during transportation and storage. Let us introduce you essential products to build efficient supply chains through realizing stable product supply.

Humidity absorbing function

Humidity absorbing function

you’ve never seen was established by chemical power.

The silica gel which is familiar among us is categorized as physical adsorption that catches humidity by concaves on the surface.

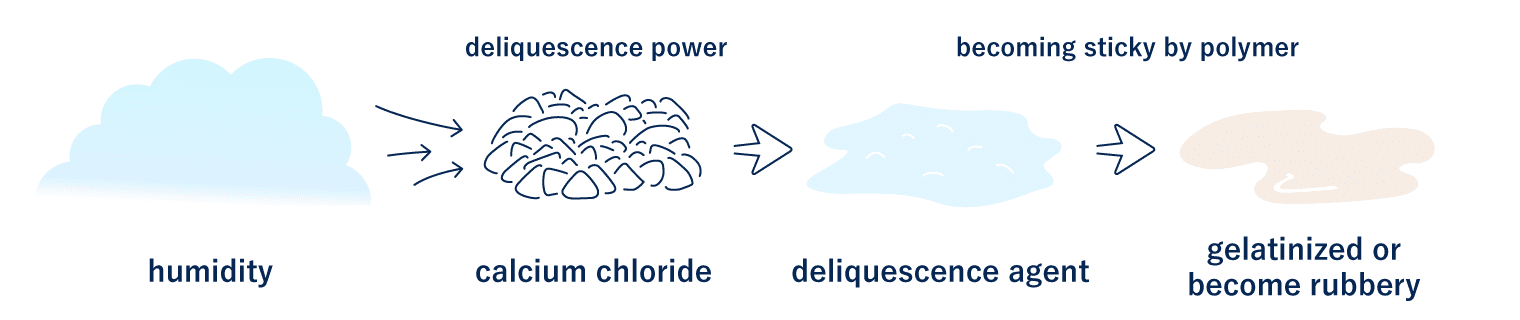

However, EX-DRY uses deliquescence power of anhydrous calcium chloride to absorb humidity; hence high absorbing function ever.

01Humidity absorbing function you’ve never seen was established by chemical power.

Strong and highly efficient absorbent.

EX-DRY’s humidity absorbing function is about five to seven times stronger than that of common silica gel.

Moreover, initial effect is superior and it lasts for a long time.

*Types of desiccant used for comparison: magnesium chloride, calcium chloride dehydrate, quicklime, silica gel, clay ore

Experimental video that compares

the dehumidifying and hygroscopicity of “EX-DRY” with silica gel

01Humidity absorbing function you’ve never seen was established by chemical power.

Break through limit of physical adsorption!

High-purity anhydrous calcium chloride which has deliquescence power absorbs humidity,

then high functioning dissolvable polymer made from natural material changes it into gel or rubber forms.

Because it uses unique technology, there is no need to worry about leak and it’s easy to check replacement time.

In addition, you can use it safely because it never causes chemical reactions like composition change, by-products,

or heat transfer while absorbing humidity.

01Humidity absorbing function you’ve never seen was established by chemical power.

Realized most suitable functions with special film

that no one can copy!

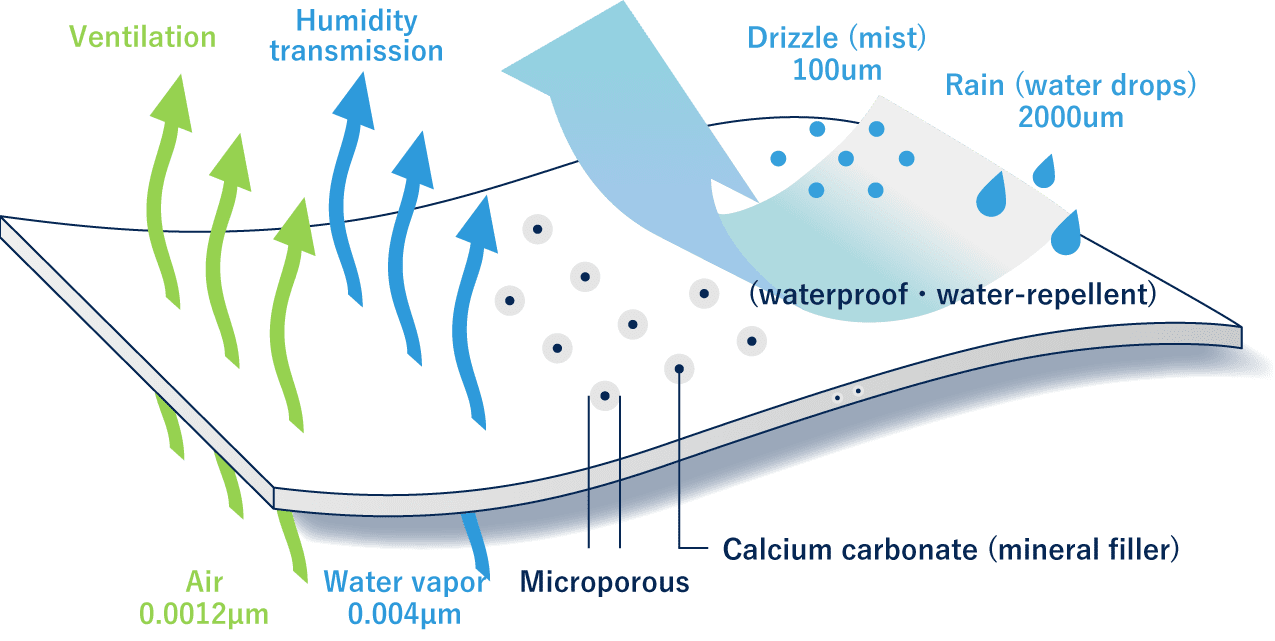

A special film which we’ve developed as a result of accumulation of much research is used for EX-DRY’s packing material.

It passes water vapor like humidity but it completely shuts out water drops like rain;

this packing material with well-balanced porous structure plays an important role.

In an effort to reach below 60% of humidity rate

In an effort to reach below 60% of humidity rate

that is suitable for transportation

Temperature and humidity at which products experience change according to countries, seasons (dry/wet) and lead times.

In some countries, humidity rate could be 90 or 95%, which could lead to various risks such as rust on metal products or mold on leather goods.

Using EX-DRY to accommodate such environmental changes realizes the best humidity and protects products from harmful humidity.

Prevent product damages caused

under high temperature and humidity circumstances

Usage examples

- Automobile industry(cast-iron parts, iron parts)

- Electronic industry(electronic parts, batteries, control panels)

- Glass industry(building materials, car windshields)

- Textile factories(workwear, jackets, miscellaneous goods)

- Food(rice, brown sugar, beverage (bottles) )

- Packing work(dehumidification in containers, wooden boxes or cartons)

For realization of

For realization of

sustainable society

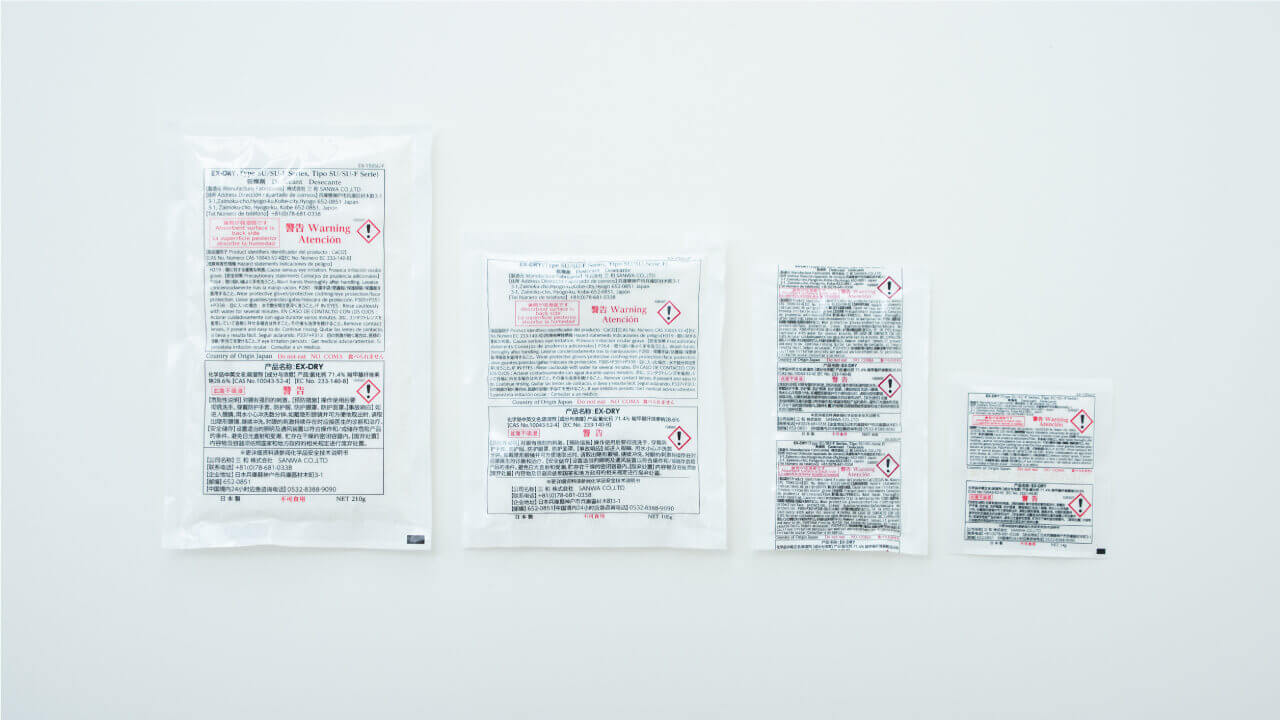

We’ve passed multiple law restrictions such as UN GHS, Europe’s REACH, and China’s GB; so you can use EX-DRY for export with no worries.

EX-DRY is eco-friendly

because of safe materials used.

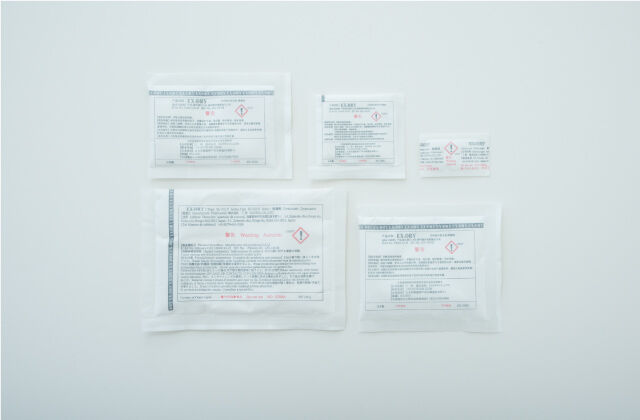

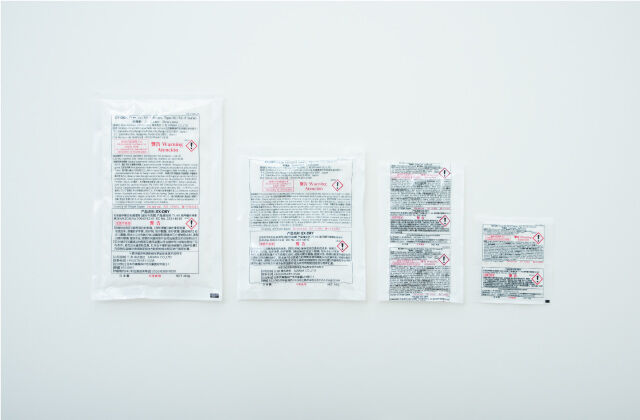

PRODUCTS

-

SU double-face non-woven fabric type

Both sides of packing material are made of non-woven fabric.

This is the most basic one. -

SU-F single-sided film type

One of the sides of packing material is made from non-woven fabric and the other is made from film.

This one is used for more delicate products like electronic parts. It absorbs humidity more slowly compared to double-face non-woven fabric type. -

SU-H hanger type

You can hang it in containers.

We will be happy to suggest an item, size, quantity and effective usage to accommodate your needs.

Please let us know your transportation or storage conditions.

FAQ

- How do I know when to replace or dispose an EX-DRY?

- It depends on use environment, so we can’t advise the exact time period.

However, as EX-DRY keeps absorbing humidity, it becomes like gel or gummies from granules.

When it becomes like gel or gummies, please replace it with a new one or dispose of it. - Is there an expiration date?

- No, there isn’t.

Only when the carton is unopened, we offer a two-year warranty. - Can I reuse it?

- No, you can’t reuse an EX-DRY that’s already become like gel after absorbing humidity.

- Can you issue a certificate of non-use?

- Yes. We can issue certificates to prove EX-DRY doesn’t contain SVHC substances or ones prohibited by RoHS2.0. We can also issue parameter sheets.